The sheet metal stamping and deep draw prototype industries are poised for solid growth in the coming years, driven by increasing demand from various end-use sectors such as automotive, electronics, and appliances. Several key business trends are shaping the future of these markets:

- Technological Advancements: The prototyping industry is embracing technological innovations to enhance efficiency and precision. The adoption of advanced CNC machines, industrial robots, and automation solutions is enabling faster turnaround times, improved part accuracy, and reduced manual intervention. Additionally, the integration of Industry 4.0 technologies, like data analytics and cloud computing, is optimizing production planning, quality control, and supply chain management.

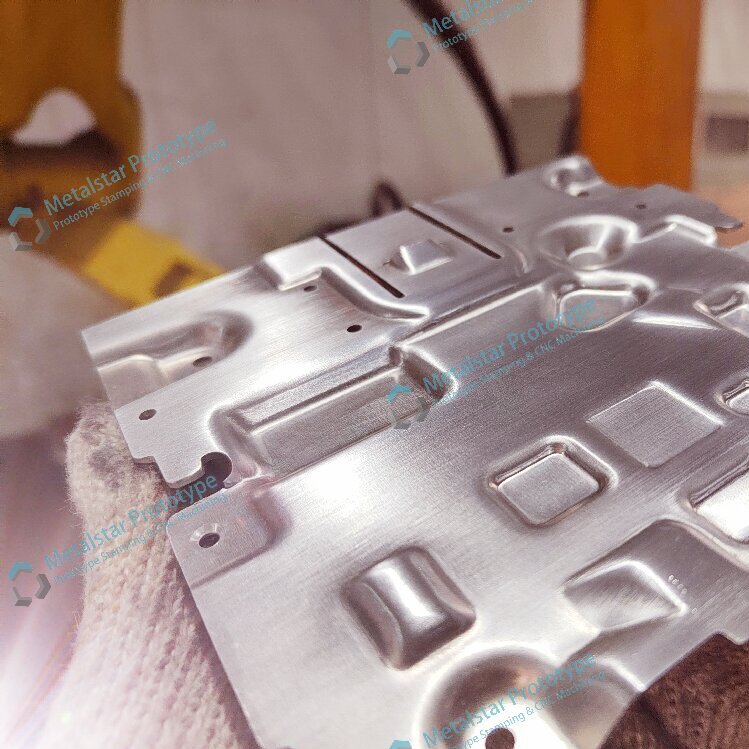

- Material Diversification: Prototype manufacturers like Metalstar Prototype are expanding their material capabilities beyond traditional steel to include lightweight and high-strength alternatives, such as aluminum alloys, stainless steel, and advanced composites. This shift caters to the growing demand for lightweight, durable, and corrosion-resistant components, particularly in the automotive and aerospace industries.

- Customization and Personalization: Customers are increasingly seeking tailored prototyping solutions to meet their unique design and performance requirements. Prototype providers are responding by offering more flexible and responsive customization services, allowing for rapid development of small-batch or even single-piece parts. This trend is driven by the need for faster product innovation cycles and the ability to quickly adapt to changing market demands.

- Sustainability and Environmental Compliance: Prototyping companies are placing greater emphasis on eco-friendly manufacturing practices to address the growing environmental concerns of their customers. This includes the adoption of clean production methods, waste reduction initiatives, and the use of recyclable or sustainable materials. Compliance with stringent environmental regulations is becoming a critical factor for success in the market.

- Global Expansion and Localization: Leading prototype manufacturers are expanding their global footprint to serve multinational customers and tap into diverse regional markets. This strategy often involves setting up local production facilities or partnerships to better understand and cater to the specific needs of each market. At the same time, there is a trend towards localized production, where prototype providers are establishing smaller-scale facilities closer to their customers to enhance responsiveness and minimize supply chain disruptions.

- Collaborative Partnerships: Prototype manufacturers are increasingly forging strategic partnerships with their customers, design firms, and technology providers to leverage complementary capabilities, share risks, and jointly develop innovative solutions. These collaborative efforts aim to streamline the product development process, improve cost-effectiveness, and deliver more comprehensive prototyping services to the end-users.

As the sheet metal stamping and deep draw prototype industries continue to evolve, these key trends are expected to drive growth, enhance competitiveness, and enable prototype providers to better serve the dynamic needs of their customers across various industrial sectors.

Start your project today! The team at Metalstar is always fulfilled with passion and professionalism to assist you to turn your innovative ideas into practical solution. Visit our website at: www.gzmetalstar.com for more information. Thank you!