The investment casting process for producing prototype parts are as following steps, in fact these steps are the same as the process for producing large-scale production investment casting parts.

1. Wax mold forming

Wax mold forming is the initial step of injecting molten wax into a mold and cooling it to obtain the wax mold, laying the foundation for subsequent processes.

2. Tree Assembly and Shell Production

The tree assembly connects the wax patterns, while the shell-making process enhances the wax patterns by applying refractory materials to prepare them for casting.

3. Dewaxing and Roasting

De-waxing involves melting the wax at high temperatures and removing the residue through roasting to ensure the quality of the mold shell.

4. Melting and Casting

After testing according to the material requirements, the molten steel is poured to ensure the composition meets the standards.

5. The finished casting is obtained

After the pouring process is completed, a complete cast product is obtained, which can undergo further processing.

▍ Advantages and Disadvantages Analysis

1. Advantages

Investment casting can produce complex parts with high freedom, dimensional accuracy, and excellent surface quality.

2. Disadvantages

Investment casting has high costs and is suitable for medium to large-scale production, with better performance for small castings and simple shapes.

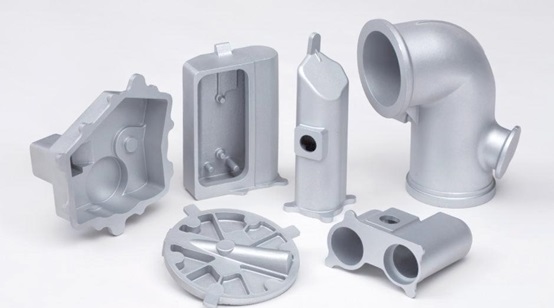

▍ Parts Suitable for Investment Casting

Investment casting is particularly suitable for small to medium-sized parts with complex internal structures and high precision requirements.

▍ Applications of Investment Casting

Investment casting is widely used in fields such as aerospace, automotive manufacturing, and artistic crafts. In these industries, it continuously drives technological advancement and innovation with its exceptional craftsmanship.