In CNC prototype machining, aluminum alloy 6061 and 7075 are commonly used materials, but their performance differences significantly affect machining efficiency, cost, and prototype quality. The following is a detailed comparison of the two in terms of chemical composition, mechanical properties, processing characteristics, cost, and application scenarios.

1. Differences in basic performance and mechanical characteristics (core foundation)

6061 aluminum alloy : with magnesium (Mg) and silicon (Si) as the main alloying elements (such as Mg2Si phase), the tensile strength after T6 heat treatment is about 310 MPa, and the elongation is relatively high (12% -17%). It has moderate hardness (HB 95), good toughness, strong corrosion resistance, excellent welding performance, and is suitable for the processing of complex structure prototypes.

7075 aluminum alloy: Zinc (Zn) is the main alloying element, supplemented by copper (Cu) and magnesium. After T6 heat treatment, the tensile strength can reach up to 570 MPa, but the elongation is low (5% -10%). High hardness (HB 150 or above), but poor toughness, prone to thermal cracking during welding, and prone to corrosion in humid environments.

Processing impact: The ductility of 6061 makes it easier to form in CNC machining, while the high strength of 7075 increases the load-bearing capacity of the prototype but also increases the difficulty of processing.

•2. Comparison of CNC machining performance (operation key)

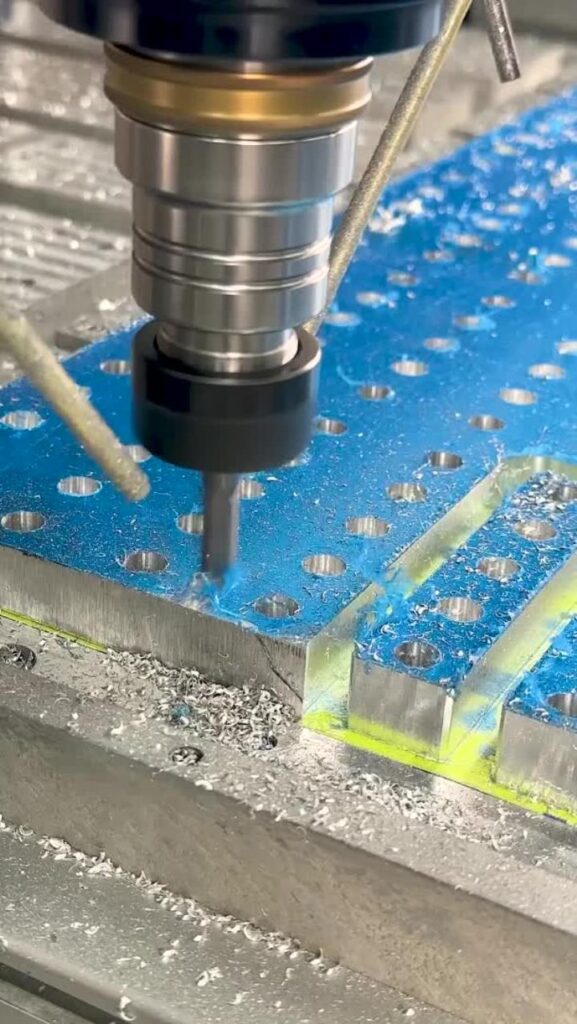

•Cutting performance and efficiency: 6061 has low cutting resistance and slow tool wear (such as longer service life of hard alloy tools), suitable for high-speed machining (feed rate can reach 3-5 m/min); 7075 has high cutting force due to its high strength (about 30% -50% higher), which can easily cause surface hardening. It is necessary to reduce the speed (1-3 m/min) and use sharp tools, otherwise tool breakage or machining vibration may occur.

Surface quality and tolerance control: 6061 has a good surface finish (Ra 0.8-1.6 μ m) after processing, low deformation risk, and is suitable for high-precision prototypes; 7075 is prone to burrs and residual stresses, requiring additional post-processing (such as sandblasting or vibration stress relief) with stricter tolerance control (± 0.05 mm).

• Cooling and parameter optimization: both need coolant anti sticking knife, but 7075 is sensitive to heat, and spray cooling is recommended to avoid overheating deformation. If users pursue rapid prototype iteration, 6061 is better; If you need to simulate high load environments (such as aerospace components), 7075 is more challenging but more realistic.

3. Cost, availability, and post-processing (economic considerations)

Material cost: 6061 has a relatively low price and sufficient market supply, making it the preferred choice for economical prototypes; 7075 has high costs and limited inventory, which prolongs the procurement cycle.

Post processing adaptability: 6061 is easy to anodize, spray and other surface treatments, enhancing its appearance and corrosion resistance; 7075 has poor weldability and uneven anodizing, often requiring professional treatment (such as electroless nickel plating), which increases prototype time and cost.

Overall cost-effectiveness: For prototype projects with limited budgets, 6061 can achieve 90% of testing requirements at a lower cost; 7075 is only recommended for high-strength and lightweight key prototypes, but has a high processing failure rate (about 15% -20%).

4. Recommended application scenarios (practical suggestions)

6061 is suitable for general prototypes (such as consumer electronics casings, car brackets), frequently iterated prototypes, and components that require welding or complex structures. Its ease of processing can shorten the delivery cycle by 20% -30%.

7075 is suitable for high stress prototypes of aerospace, military or sports equipment (such as aircraft joints, bicycle frames), which cannot be replaced in tests with high strength to weight ratio requirements.

If the prototype does not require extreme loads, prioritize 6061 to save costs; On the contrary, although 7075 is difficult to process, its ultimate performance can be verified. It is recommended to conduct small-scale trial processing to evaluate feasibility.

In CNC prototyping, 6061 is known for its ease of processing and low cost, making it suitable for most prototype development; 7075 is known for its high strength, but it presents significant processing challenges and high costs. Users need to choose 6061 to optimize efficiency and economy, 7075 to meet high-performance requirements based on prototype functions such as test load and iteration speed. Recommend combining CAD simulation to predict machining stress and reduce material waste. In the end, the difference between the two highlights the balanced art of materials science in prototype design -6061 represents the “practicality” and 7075 represents the “performance”.