Precision CNC machining has a very broad future market prospects, mainly due to the automation and digital transformation of the global manufacturing industry, as well as the increasing demand for high-precision and high complexity parts processing.

Market demand and industry applications

Precision CNC machining technology is widely used in various fields, including aerospace, automotive manufacturing, electronics industry, medical equipment, etc. The continuous development of these industries has led to an increasing demand for high-precision and high complexity parts processing, driving the growth of the precision CNC machining market. In addition, with the increasing demand for personalization and customization in the manufacturing industry, precision CNC machining enterprises can provide customized services to meet customers’ special needs.

Technological innovation and intelligent trends

Precision CNC machining technology is developing towards intelligence and networking. Modern CNC systems integrate more sensors and communication technologies, enabling more efficient production and more precise control. For example, numerical control systems not only control the mechanical motion of machine tools, but also optimize the machining process through data acquisition and real-time feedback, ensuring machining accuracy and improving efficiency. In addition, the promotion of intelligent manufacturing has greatly improved the production and manufacturing capabilities as well as product quality of CNC machining centers.

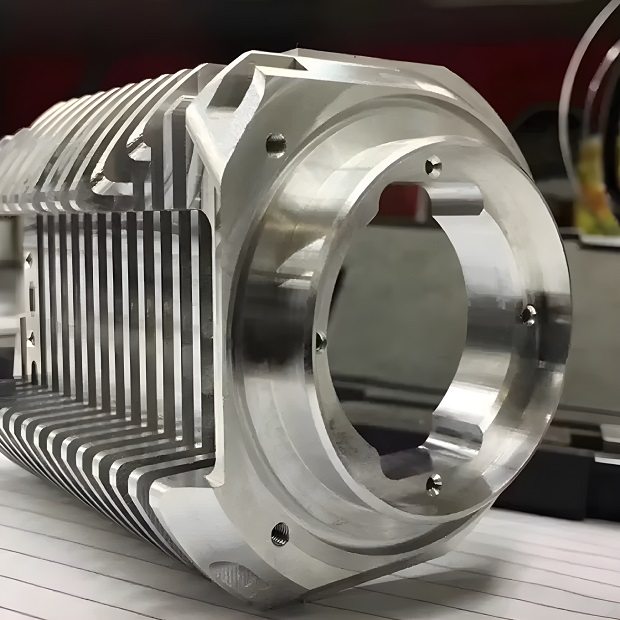

Metalstar Prototype provides one-stop precision CNC machining services with high cost-effectiveness and fast processing of materials including aluminum alloy, carbon steel, titanium alloy, brass, plastic, etc. Please visit our website at: www.gzmetalstar.com to learn more about our machining capabilities and capacities. Thank you!