Safety aspect

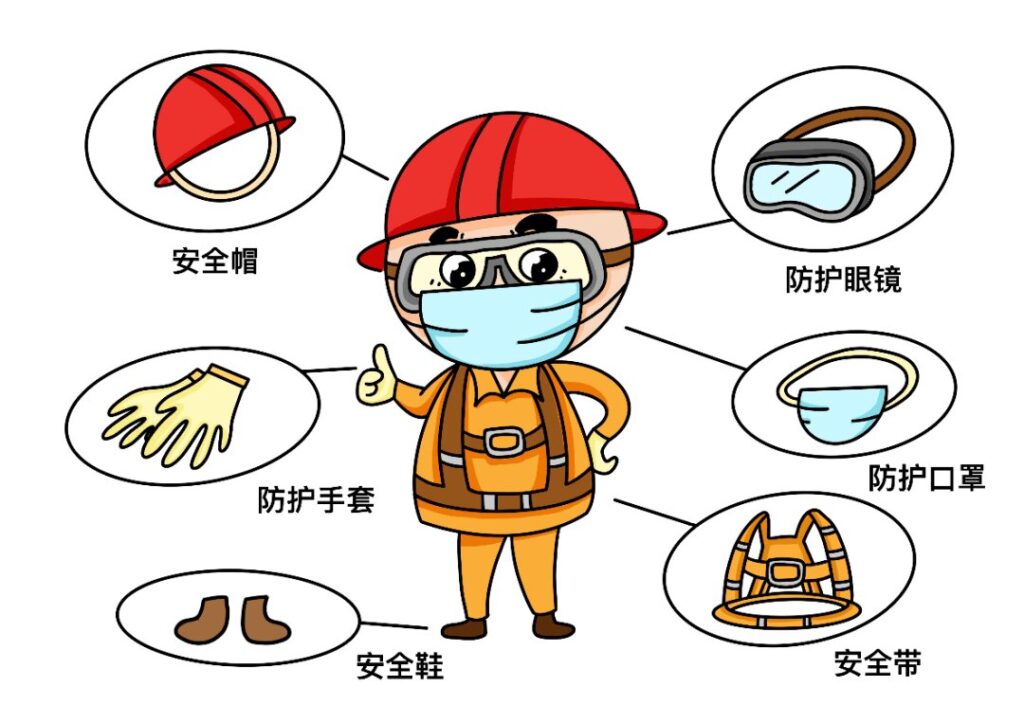

Personal protective equipment: Operators must wear cut resistant gloves, safety glasses or goggles, hearing protection devices (such as earplugs or earmuffs), safety shoes, as well as welding caps and protective clothing when welding or cutting.

Equipment operation safety: When operating stamping machines, shearing machines, bending machines, laser cutting machines and other equipment, it is necessary to strictly follow the operating procedures, check whether the various components of the equipment are normal, and adjust the relevant parameters. At the same time, protective devices should be installed on the rotating parts, cutting areas, and electrical components of the equipment to prevent personnel from coming into contact.

Chemical safety: Chemicals should be stored in a classified manner, flammable and explosive materials should be kept away from sources of fire and heat, toxic substances should be managed with locks and clearly labeled. When using chemicals, it is necessary to wear appropriate protective equipment to avoid generating dangerous factors such as static electricity and sparks.

Emergency situation handling: In case of an emergency, quickly press the emergency stop button of the equipment, evacuate personnel, report the accident situation, and carry out rescue in a timely manner.

In terms of processing quality

Positioning accuracy: Before processing, it is necessary to strictly check the design drawings, arrange the processing sequence reasonably, select the appropriate processing technology, and ensure the positioning accuracy of the parts.

Processing state parameter control: Strictly control the temperature, pressure, speed, time and other parameters during the processing to ensure the stability and consistency of the processing quality.

Deburring treatment: No matter what processing method is used, burrs will be generated, which need to be removed by manual polishing or deburring machine to ensure that the burrs are removed to a degree that does not cut hands.

Bending process: The accuracy of the bending process affects the subsequent welding process, and fine adjustments need to be made according to the material batch and rolling direction during bending.

Welding process: When welding, the choice of welding method should be considered. For example, laser welding can achieve low deformation welding of thin plates, but it is not good at surfacing.

Quality inspection: After processing, professional testing equipment and methods should be used to comprehensively inspect the appearance quality, dimensional accuracy, strength, and other aspects of the product.

Other aspects

Equipment maintenance: Regularly clean and lubricate equipment, check the condition of equipment and wear of parts, replace or repair equipment in a timely manner, and ensure the normal operation of equipment.

Work environment: Keep the workshop clean and tidy, arrange materials neatly and orderly, leave personnel and transportation channels, and avoid oil stains on the ground.

Personnel training: Reasonably allocate human resources, select personnel with different skill levels for different processing stages, and provide them with necessary training and skill improvement courses.